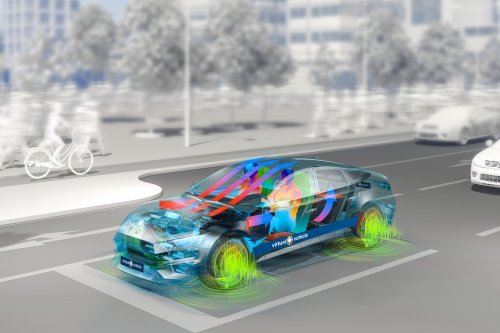

VIRTUAL VEHICLE – Enabling Future Vehicle Technologies

With over 300 employees, Virtual Vehicle Research GmbH is Europe's largest research center

for virtual vehicle development in the rail- and automotive sectors targeting interdisciplinary

cutting-edge research for climate-neutral mobility while successfully transferring its methods

and tools to other domains as well.

With its focus on industry-related research, VIRTUAL VEHICLE is an innovation catalyst for

future vehicle technologies in the era of digitalization and mobility transition securing

sustainable competitive advantages for its research partners.

VIRTUAL VEHICLE cooperates with around 100 national and international industrial

partners (OEMs, tier-1 and tier-2 suppliers and software providers). Partnerships with around

50 scientific institutions form a solid basis for driving innovations for vehicle technologies of

the future. VIRTUAL VEHICLE is Austria’s largest COMET funded research center and is

also active in 35+ EU-projects. In addition, VIRTUAL VEHICLE offers a broad portfolio of

contract research for the vehicle development.

Our Fields of Expertise:

• Reliable System Simulation

Over nearly two decades, VIRTUAL VEHICLE has played a pivotal role in advancing

industries by fostering the creation of superior, safer, and economically efficient products.

This has been made possible through the establishment of cutting-edge technology for system

simulation and the acquisition of key international patents. The applications of these

advancements are diverse, serving to streamline setup and configuration processes among

other benefits.

• Virtual Validation

Safety validation is crucial in automotive and railway development. However, traditional

physical testing faces limitations in terms of cost, time, and scalability. At VIRTUAL

VEHICLE, we’re advancing technology to transition testing scenarios into virtual reality. By

leveraging reality-based simulations, we’re enhancing safety standards and enabling virtual

homologation.

• Continuous Integration

Common test methods include model, software, or hardware-in-the-loop systems, which are

integrated for cost-effective testing. This integration generates test and simulation subsystems

that require seamless data exchange. Ideally, test cases are supplied, parameterized, executed,

analyzed, and reported, which emphasizing the importance of continuous data integration

throughout the process.