BDI-BioEnergy International GmbH is an internationally active special plant manufacturer and is committed to valorization of residual and waste materials. The company’s core business is the development of BioDiesel production technologies from waste oils and fats, thus, presenting a valuable contribution to minimizing the ecological footprint. With GreenTech Solutions, BDI supports its customers in developing and scaling-up liquid phase chemical processes to get technologies from laboratory scale to industry maturity. BDI-BioEnergy International GmbH has currently around 100 employees.

BioDiesel

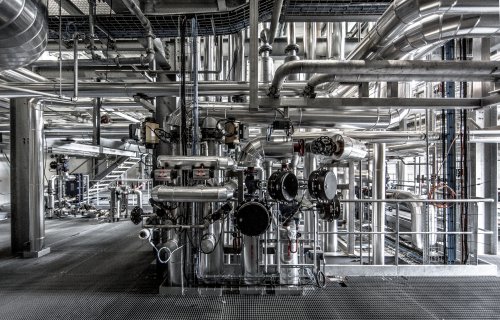

Multi-Feedstock technology by the market leader

With the patented Multi-Feedstock technology, BDI guarantees an highly efficient economical production of BioDiesel from waste-based oils and fats from industry and trade. By using BDI’s RepCAT technology, it is – in contrast to common BioDiesel processes – possible to process feedstock with an FFA content up to 100% and to avoid a costly processing of by-products. Furthermore, the usage of a recyclable catalysator enhances the end products’ (BioDiesel and glycerin) quality decisively.

RetroFit

Plant optimization by the technology leader

Even the latest biodiesel plant will not be any more state of the art at some point. By implementing BDI’s RetroFit program, existing large-scale plants become more profitable and future-proof. To reach an optimum result, it is necessary to develop a tailor-made concept and implement the best possible technical solutions regarding plant security and energy efficiency, increased profits or enhancement of feedstock flexibility. The outcome is a sustainable enhancement of the technical and economic plant performance.

PreTreatment for Renewable Diesel

To produce renewable diesel and sustainable aviation fuel (SAF), refineries bank on various oils and fats as feedstock, from fresh soy oil to waste oil to animal fats from rendering. Such processes put high demands on the feedstock quality and require extremely low contamination levels, e.g., through phosphor or metals. If the raw material is used in co-processing plants in which the reactors are not designed for a certain acid content, corrosions may occur. BDI has a more than 25-year-long experience in the Advanced PreTreatment process – a flexible and modular method to process various types of oils and fats.

GreenTech Solutions (GTS)

GTS is BDI’s full-service engineering and consulting department and forms the links between innovative idea and successful economical implementation of liquid phase chemical technologies. In this regard, the service portfolio spans from commissioned research and process development to engineering and scale-up services to customer service.